![]()

- History of development INDEX >>>

- Chronicle >>>

- Our Pride >>>

- Development story vol.1 >>>

- Development story vol.2 >>>

- Development story vol.3 >>>

|

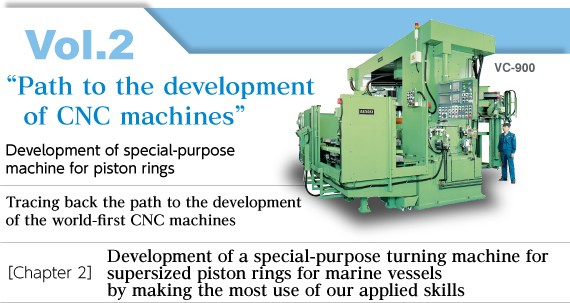

In 1998, KATAOKA received request from Dalos Corporation in Sweden for the development of a special-purpose machine for large-sized piston rings for marine vessels. Dalos is an over 100 year-old manufacture of piston rings for marine vessels with over 200 employees and a large turnout. The requested machine was for supersized rings of φ300 – 1100mm, while KATAOKA had developed machines for φ60 – 600mm rings for various industries, including automobiles and marine vessels. President Kataoka and design engineers flied to Sweden with enthusiasm. |

|

Having listened to the presentation to the end, President of Dalos said eventually, “We aren’t interested in your machines at all.” The reason was as clear as a bell. Japanese manufacturing is “process distributed” with many machines and workers for completing one product. In contrast, the Swedish manufacturing is “process intensive” with a multifunctional machine and multiple processes with less number of workers. After the presentation, the KATAOKA troupe observed the factory of Dalos and saw one machine of mechanical control type. It was a typical “process-intensive” machine. The inside and outside diameters of cylindrical materials were elliptically processed and picked up by a robot immediately before cutting off. |

||

|

After observing the factory, President of Dalos said to President Kataoka, “If you can change this machine into a CNC machine, I’ll give you an opportunity.” By then, however, President Kataoka had already had the odds. We had already developed a machine for processing the inside and outside diameters of small-sized oval rings as seen in the “DCM-1” (See Chapter 1). As the load on the cutter also increased with the increase of the ring size, the rigidity of the machine was essential, but as the turning speed could be reduced, there was small risk on KATAOKA. For these reasons, President Kataoka was confident that he could meet the request from Dalos. Upon returning home, the development team made up the scheme of “VC-900,” a full-automatic rough-finishing machine for O.D. & I.D. cam turning of supersized piston rings. This machine not only elliptically processes the inside and outside diameters under CNC but also processes outside diameters to various shapes, chamfering, inkjet marking for subsequent gap milling and cutting-off in the last process and unloads finished rings to the outside of the machine. The “VC-900” alone takes care of all these combined processes. Thus, a process-intensive CNC special-purpose machine living up to the expectations of Dalos began to be embodied. |

However, at the time of the final quotation, Dalos called a halt to the project saying, “Investment efficiency is too low.” In Sweden, as the wage level is high, further robotization is a must. There, KATAOKA counter-offered an “automatic pallet changer (APC).” With the APC, one operator could discharge the processed work from the machine and set new work on the machine. By adding “something extra” to Dalos’ needs, we cleared the problem with investment efficiency. One month later, KATAOKA received from Dalos an order for two APC-equipped special-purpose machines. The “VC-900” developed by making the best use of the idea of the “DCM-1” and our techniques accumulated for a long time is the fruits of the development power that only KATAOKA possesses. Not only meeting customers’ needs, but also proposing something extra. This is the very style of KATAOKA’s unflinching development. |

|

When President Kataoka witnessed the delivery of the “VC-900” in 1999, President of Dalos handed over a thick file to him, saying, “Open this.” President Kataoka looked through it. It was a company brochure of Dalos. He found there an article of “VC-900” appealing its performance in a big way.

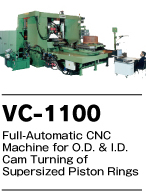

President Kataoka looked back to that time. “I read that brand-new company brochure. It must have been printed immediately before the delivery of the “VC-900” to Dalos. I realized how Dalos put its trust in our products.” After that time, Dalos expanded its share remarkably. Four years later, another fruit was born. We received an order from Dalos for the Full-Automatic CNC Combined Machine for O.D. & I.D. Cam Turning and Marking of Supersized Piston Rings “VC-1100,” and started its development. |

![“Path to the development of CNC machines”[Chapter 1]](img/story_side_bn01.jpg)

![“Path to the development of CNC machines”[Chapter 2]](img/story_side_bn02.jpg)